Application:

EKO-BO Series Waste engine oil to base oil distillation plant is particularly used in many industries such as mines, metallurgy, electric power, transportation, mechanical manufacture in which lubrication oil like hydraulic oil, engine oil, diesel oil, cooling oil, Motor oil, Car oil etc are used. Gas engine oil/ diesel engine oil used in the field of transportation like shipping, land-carriage etc. also can be distillated and produced both base oil and diesel oil by EKO-BO series machines.

Features:

EKO-BO Waste engine oil to base oil distillation plant combines latest technologies. It is able to extract light and heavy distillates from different fractions rapidly by given different temperatures control along with our own formulated catalyst compound. It can also remove the Metallic Compound, light hydrocarbons, water and asphaltene sludge,and reduce the Sulfur content etc , during re-refining process. The end product after distillation could be new base oil according to the customer demands.

EKO-BO Waste engine oil to base oil distillation plant adopts exclusive patent and design the re-refining technologies for used lubricating oil to produce near virgin quality base oil ranging from SN150 to SN500 by using different technolologies,Such as full continuous distillation, wiped film evaporation and short path distillation. In the meanwhile, we have developed base oil solvent extraction plant to help you to get rid of annoying clay refining system and allow you to refine the base oil to meet API group 1+ standards. About the diesel production,it adopts exclusive fractional and special desulfuring technologies, the diesel which is produced by our distillation plant is able to meet Euro-V related standards.

Advantages

1. Fractional tower is more accurate and the oil quality is improved.

2. Increase fractional tower to realize continuous operation.

3. Effective use of waste heat recovery, saving energy and reducing consumption.

4. The valve tray replaces the traditional packed tower, reducing consumables and improving production efficiency.

5. Make full use of the reflux tower to prevent the production of more light components and improve the recovery rate.

6. Added auxiliary configurations for customers to choose according to their own requirements (as follows)

a. Flue gas heating: fuel oil, natural gas, coal and other fuels can be used instead of electricity. (The cost of construction is high, and the daily processing capacity is less than 50 tons. It is not recommended to choose)

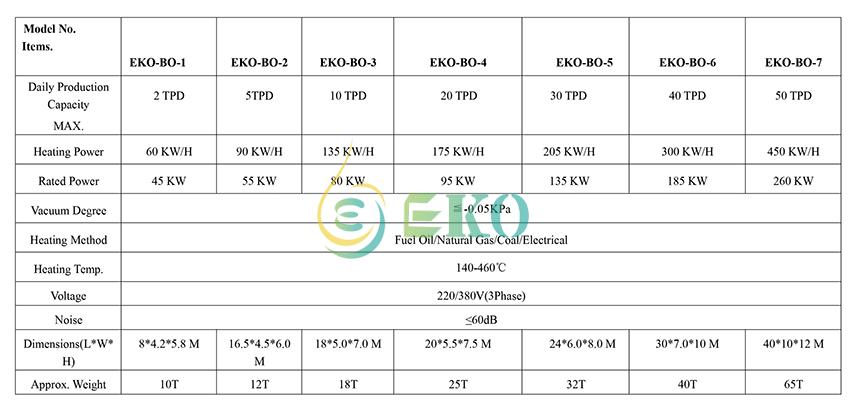

PARAMETERS

How to get good quality of base oil from engine oil?

Our waste oil regeneration molecular distillation equipment adopts vacuum atomization flash distillation technology, which is different from traditional distillation which relies on boiling point difference separation principle, (for example, traditional boiling point difference separation is about 450 ℃, while high vacuum short-path molecular distillation technology is about 350 Either).

Instead, the liquid-liquid separation is achieved by the difference in the mean free path of the molecular motion of different substances. The free path of molecular motion refers to the distance traveled by a molecule between two adjacent collisions. When the oil is heated, the light and heavy molecules of the oil will overflow the liquid surface and enter the gas phase. Because the free paths of the light and heavy molecules are different, the molecules of different substances move differently after overflowing from the liquid surface to achieve material separation. the goal of. The vacuum atomization flash distillation technology not only speeds up the molecular overflow time, but also improves the oil yield. The final product can be refined to obtain high-quality base oil.

The oil samples:

Name: Krystal Li

Mobile:+8615523108272

Tel:+8615523108272

Whatsapp:2356

Email:oilrecycling@ekomachinery.com

Add:No.2999 Longzhou Ave.Longzhou street,Banan District,Chongqing,China