Application

1. This vacuum lubricant turbine oil filtration dehydration machine is widely used in hydro-power system, electric power, chemical industry, paper-making, petroleum and other industries. And dealing with the unqualified lubricant oil, turbine oil and hydraulic oil. The machine was equipped with precision filtration, vacuum drying, coalescence separation and three - dimensional spiral atomization technology, after the treatment, the water, gas, moisture,acid, particle and foaming in the aging oil will become clear and can be used again. It can do online and offline work. It is an ideal equipment for purification of turbine and hydraulic oil. And It can ensure the safe operation of steam turbine lubrication system effectively.

2. Aiming at lubrication system - dehydration, degassing and impurity removal, improve the cleanliness of lubricating oil system effectively.

3. it can be used for Hydraulic oil, Lubricating oil, Turbine oil purification.

Features

● The vacuum lubricant turbine oil purifier can remove 100% free and dissolved water, The water content is less than 50 ppm.

● Can also remove 100% free and dissolved gas, and the gas content is not more than 0.2%.

● The machine can do online and offline processing in turbine and hydraulic dilute oil station, high automation, compact type volume, flexible movement.

Optional

● Outdoor weather-proof enclosure

● Trailer mounted type to increase mobility

● Explosion-proof type

● PLC & HMI touch panel control

● Automatic water drainage

● Customizable design, material and components

Technical Parameters

|

Model Item |

Unit |

EK-L20 |

EK-L30 |

EK-L50 |

EK-L80 |

EK-L100 |

EK-L150 |

EK-L200 |

EK-L300 |

||

|

Flow |

L/Min |

20 |

30 |

50 |

80 |

100 |

150 |

200 |

300 |

||

|

Working Vacuum |

Mpa |

-0.08~-0.096 |

|||||||||

|

Working Pressure |

Mpa |

≤0.5 |

|||||||||

|

Working Temp. |

℃ |

≤10~80 Adjustment |

|||||||||

|

Power Supply |

V |

380V-480V-50Hz-60Hz (Customized) |

|||||||||

|

Heating Power |

Kw |

24 |

30 |

36 |

42 |

54 |

66 |

72 |

90 |

||

|

Total Power |

Kw |

26 |

33 |

39 |

45 |

57 |

72 |

86 |

105 |

||

|

Inlet/Outlet Pipe |

Mm |

Φ25 |

Φ32 |

Φ42 |

Φ42 |

Φ48 |

Φ48 |

Φ50 |

Φ60 |

||

|

Weight |

Kg |

480 |

550 |

600 |

1050 |

1150 |

1450 |

1600 |

2200 |

||

|

Dimension |

L |

mm |

1150 |

1350 |

1400 |

1500 |

1550 |

1550 |

1600 |

1650 |

|

|

|

W |

mm |

910 |

1000 |

1100 |

1300 |

1350 |

1350 |

1400 |

1450 |

|

|

|

H |

mm |

1550 |

1600 |

1650 |

1750 |

1800 |

1850 |

1900 |

2000 |

|

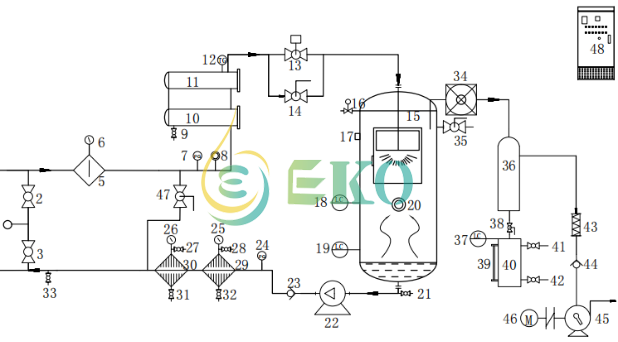

Flow Chart

|

After Treatment Parameters

|

Items |

Unit |

After |

Test method |

|

Particles |

% |

No |

NAS1638 |

|

Demulsification value |

Min |

≤15 |

GB/T7605 |

|

Water |

ppm |

≤40 |

GB/T7600 |

|

Acid |

mgkoH/g |

≤0.3 |

GB/T264 |

|

Gas |

% |

≤0.1 |

|

|

Cleanliness |

grade |

more than class 6 |

NAS1638 |

Oil Comparision

Name: Krystal Li

Mobile:+8615523108272

Tel:+8615523108272

Whatsapp:2356

Email:oilrecycling@ekomachinery.com

Add:No.2999 Longzhou Ave.Longzhou street,Banan District,Chongqing,China