Application

Transformer Oil Purification Degasifier Equipment is specially designed for used emulsified dielectric fluids used in varies transformers.

The machine with 2 types, one is double stages for large power transformers, another is single stage for small distribution transformer.

The transformer oil treatment machine can remove the water, gas and solid particle from the used oil, and the breakdown voltage can be improved greatly up to 75kV.

The insulating fluid requires purification regularly for the in-service insulating fluid, so as to improve electrical insulation properties and extend its lifespan.

Besides, the oil dehydrators can also act as a vacuum pump system for transformer evacuation and perform vacuum oil filling tasks.

General Details

● Several models available to achieve different functions.

● Powerful combination of rotary vane vacuum pump & Roots mechanical booster.

● Low watt density heating element

● Duplex 3D evaporation technology

● Removes moisture down to 3 PPM and less

● Remove gas contents down to 0.1% by volume

● Three stage filtration arrangement

● Remove 99.5% particulates larger than 1 micron

● Optical fluid level control system

● Interlocked preventive mechanism

● On-line vacuum oiling and purifying

Optional

● Outdoor weather-proof enclosure

● Trailer mounted type to increase mobility

● Explosion-proof type

● PLC & HMI touch panel control

● Customizable design, material and components

Technical Parameters

Model

Item

Unit

EKO-TP30

EKO-TP50

EKO-TP100

EKO-TP150

EKO-TP200

EKO-TP300

Flow Rate

LPH

1800

3000

6000

9000

12000

18000

Work vacuum

Mpa

-0.08~0.098

Work pressure

Mpa

≤0.5

Work temp.

℃

45-75 Adjustable

Power supply

V

Customized

Heating power

KW

30

36

72

96

144

180

Total power

KW

33

40

76

102

152

190

Diameter of intel&outlet

mm

Φ32

Φ38

Φ42

Φ48

Φ64

Φ76

Weight

Kg

685

850

1200

1650

2300

3100

Dimensions

L

mm

1100

1200

1450

1700

1750

1800

W

mm

950

1000

1150

13500

1450

1500

H

mm

1450

1500

1700

2000

2000

2100

Note: The dimension and weight is updating according to the improving technical. Pls take the real product as standard.

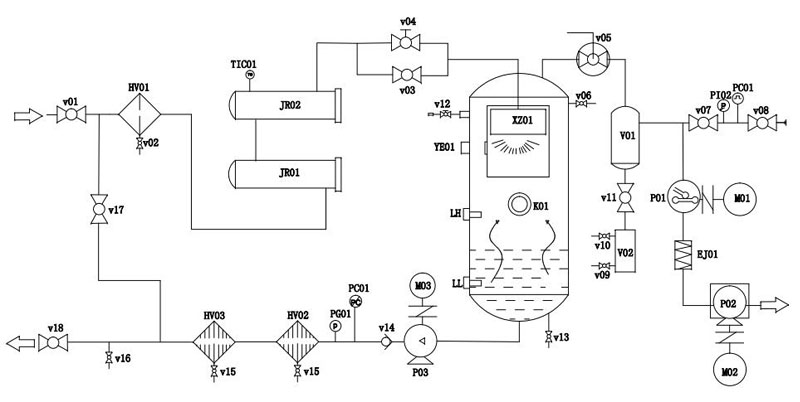

Flow Chart

After Treatment Parameters

|

Items |

Unit |

After Treatment Index |

Testing method |

|

Mechanical impurities |

% |

No |

GB/T511 |

|

Demulsification value |

Min |

≤30 |

GB/T7605 |

|

Water Content |

Mg/L |

≤3PPM |

GB/T7600 |

|

Acid value |

mgkoH/g |

≤0.3 |

GB/T264 |

|

Cleanness |

Grade |

6 |

NAS 1638 |

|

Breakdown voltage value |

kV |

≥70 |

GB、DL Or IEC Standard |

|

Residual gas |

≤0.01% |

≤0.01 |

The gas content measurement according to the standard of GB, DL and IEC |

|

Acetylene |

Mg/L |

0 |

The gas content measurement according to the standard of GB, DL and IEC |

|

Filter precision |

1-5um |

||

Oil Comparision