1.Technical Application

CGC Series Varnish Removal Unit is mainly used to remove the dissolved and suspended soft pollutants in turbine oil.So-called soft pollutant is oil varnish’s precursor which is caused by system shot spot such as bearings and pumps.The existing forms of the soft pollutants are dissolved and suspended, while these soft oxides removal can avoid oil varnish generation.Once oil varnish forms, machinery fault or boot failure by valves adhesion and out of control occurs,clogging and limitation of flow leads to oil temperature rising and increased abrasion, attachments on sandpaper surface increase element’s wear rate,disabled heat exchanger lifts oil temperature, stoving varnish formed on bearings and limitation of low increases abrasion and temperature,and frequent oil

replacement and system washing.When the soft pollutant dissolves in oil,the typical oil temperature situation overtops 40℃,then normal mechanical filtration shall be disabled.

Our Varnish Removal Filter is a composite consisting of a cellulose fiber matrix and other materials that give it a high-void volume and an open-fiber matrix.The resin-bonded,open-fiber matrix provides high permeability, which is necessary for the fluid to come in contact with the large fiber surface area for the absorption of the varnish precursors.The specially formulated binder resins give the filter media high affinity for the polar varnish precursors,resulting in high removal efficiency and retention of the material suspended in the fluid phase.

2.Features & Benefits

2.1Degradation products; oxides, resins / sludge,and varnishes are blocked by cellulose materials,this material can block about 4-16 kg of oil degradation products.

2.2It Will not cause the turbine to trip or jam the valve due to varnish 2.3 Prevent uncontrolled downtime and reduce maintenance costs 2.4Extend the life of oil and components

2.5No need for system flushing and water tank cleaning.

2.6The particles can be filtered out; 98.7% of the solid particles larger than 3um and 50% of the particles larger than 0.8 um can be blocked in the primary filtration. The amount of pollution is 4-16 liters

2.7The water absorption can reach 50% of the total capacity of contaminant (that is 2000-8000ml water).

3.Working Principle

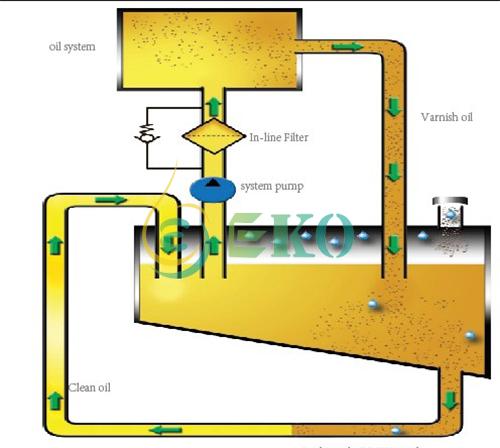

3.1The CGC is designed to remove dissolved and suspen-ded soft contaminants by polar attraction in the optimized,cellulose based CGC Varnish Removal inserts,

3.2The hot oil is drawn from the lowest point of the system tank to the CGC Varnish Removal Unit by means of the transfer pump on the unit.The process inside the unit includes pass-ing the oil through the efficient CGC Varnish Removal insert,specially designed for varnish removal in combination with the CGC Varnish Removal Unit.After cleaning,the oil is returned to your system.

3.3The varnish free oil will start cleaning all system components it comes in contact with, ulti- mately resulting in a completely varnish free system. The varnish level in the oil will typically be cut in half within a few weeks of operating the CGC.

6.Configurations: